For years now, Mahoney’s Utility Finish has been our go-to finish for salad bowls and wooden utensils. It’s made by professional woodturner Mike Mahoney.

Mike produces hundreds of bowls each year and needed a durable, nice looking, food-safe finish that can be easily and safely re-applied by his customers. Unsatisfied with what was available, he produced his own finish. Once Mahoney’s utility finish is dry, it’ll leave a rich, durable food-safe finish that won’t evaporate and lasts a long time.

Mahoney’s finishes are made with pure Walnut oil that is very high in linoleic acid. This particular acid is what gives the oil its ability to dry and sets it apart from culinary walnut oils sold at grocery stores.

Prepare the Work

Before applying the finish start by making sure your piece is sanded through at least 400 grit and has been wiped clean of dust.

Finish with Utility Finish

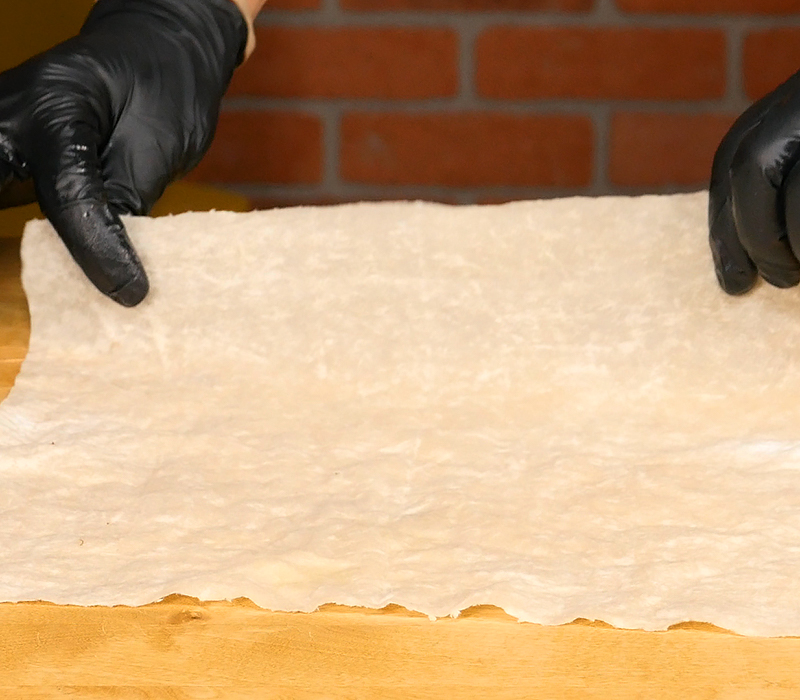

Brush or wipe on a liberal coat of Mahoney’s oil onto the piece. Let it soak in for about an hour.

Check it every 15 minutes or so and add more oil to any dry spots that may show up.

After it has had an hour to soak, wipe it dry with a clean cloth. Always properly dispose of the oily rags by laying them out to dry before discarding them.

Your project is safe to use even before the oil hardens.

Finish with Walnut Oil Wax

You can leave this as a stand-alone finish, but I’ll add some walnut oil wax to build the sheen up a little more.

You’ll want to give the oil a few days to harden in a room temperature environment before applying the wax, because if the wax is applied while the piece is wet, you’ll just be smearing it around.

Now that this piece has had a few days to dry, I’ll rub the wax on with a soft cloth. Let it sit for about an hour, then buff it dry with a clean soft cloth or buffing wheel.

You’ve now got yourself the perfect walnut oil finish that’s food-safe, all-natural and very easy to maintain.

After using your salad bowl for a while, you may need to re-apply a coat of walnut oil wax to keep the wood from “drying out”. Just follow the same steps when you need a fresh coat and you’re good to go.

Products Used

Mahoney’s Finishes Utility Finish

Mahoney’s Finishes Walnut Oil Wax

Nitrile Gloves

the first bottle of mahoneys walnut oil worked very weel. The second bottle developed a bad (rancid?) smell. I tried using it and the bad smell transferred to the wood. What happened?

Question: I found a container of walnut oil wax in the back of my cabinet, don’t know long it’s been there. The wax looks okay but it is hard and sticky. Is it to old and just trash it or can it be brought back to life somehow?

Unfortunately no, there is nothing that can be done to save the wax – once it has polymerized like that there is no turning back. Sorry!

A very nice piece on an excellent finishing process. However, there are some inaccuracies. The refined walnut oil used here has no higher concentration of lenoleic (lin-o-LAY-ic) acid than does the light yellow purified walnut oil found in the grocery store. Both are between 60% and 80% linoleic acid. The purified walnut oil has a slightly higher content of alpha-lenolenic (len-o-LEN-ic) acid, the omega-3 fatty acid that makes walnut oil a heart smart oil and is very important in initiating the crosslinking reaction we call “drying”. The purified walnut oil should not be mistaken for the “roasted walnut oil” that has started to appear for culinary use. The roasting process does reduce the linoleic content slowing the crosslinking but producing a delicate roasted flavor.

What about people with nut allergies, what finish would you recommend in that case?

If you are worried about nut allergies we recommend using a mineral oil instead like Terra Nova NaturOil

How about washing?

You definitely don’t want to soak or submerge it in water. To clean we recommend using a rag with warm soapy water and wiping it down, then drying it right away.