One of my favorite turning projects is a set of pepper and salt mills. They look great on the table and they get used nearly every day. These deluxe mills have long been customer favorites due to their high-quality components and rugged design. The pepper mill features a stainless-steel grinder and the salt mill uses a non-corrosive ceramic grinder. The coarseness of the grind can easily be adjusted with a simple twist of the knob at the top of the mill.

I’ll be turning a 12” deluxe pepper mill in this article but the process is identical for turning the Deluxe Salt Mill.

Prepare the Blank

Choose a hardwood blank that is exactly 1″ longer than the mill shaft. For this project I cut my blank to 13″ since I’m turning a 12″ mill. Keep in mind that certain woods are allergens, like cocobolo, and it might not be the best choice for a mill. I’m going to turn this mill out of walnut.

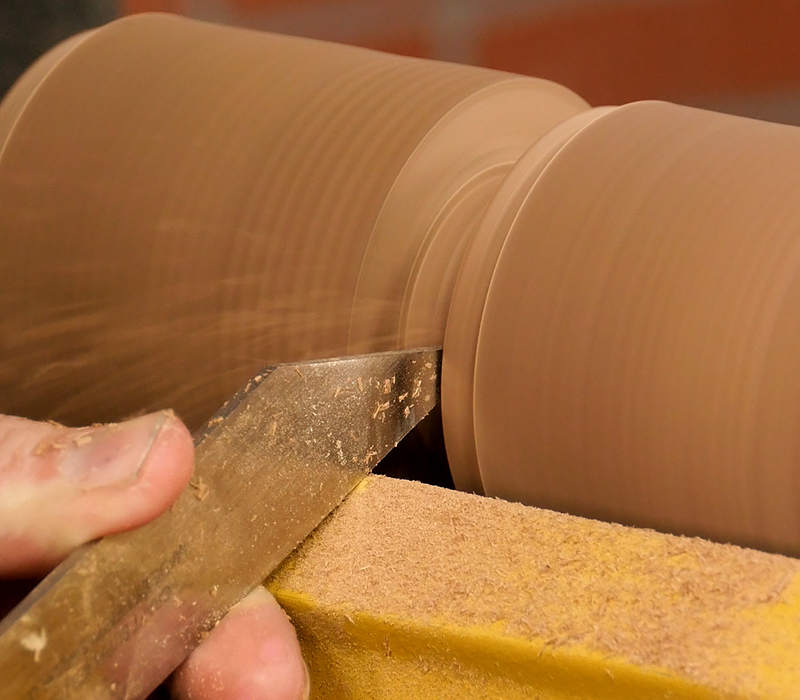

Mount the blank between centers and set your lathe speed to around 2500 rpm. Now use a spindle roughing gouge to rough the blank to round.

Layout the mill head, mill body, and the spigot marking the boundaries and labeling the mill body to keep track of grain alignment. On this mill I’m going to make the head about 3″, you can make the head any size you want – just make sure to mark out 1/2″ between the head and body for the spigot.

Cut a spigot 1/2” wide to a diameter approximately 1-1/8”. This creates a spigot that’ll fit into the mill body later. Don’t part too far, we’ll resize it later.

Now we are going to cut 3 different tenons for holding the mill at later stages. Each tenon will be cut with a skew laid on its side. Cut the first on the headstock end of the mill head and the other two tenons on each end of the mill body.

Once that our tenons are cut, use a narrow parting tool to part the separate the mill head and mill body, leaving the spigot on the head.

Drill the Mill

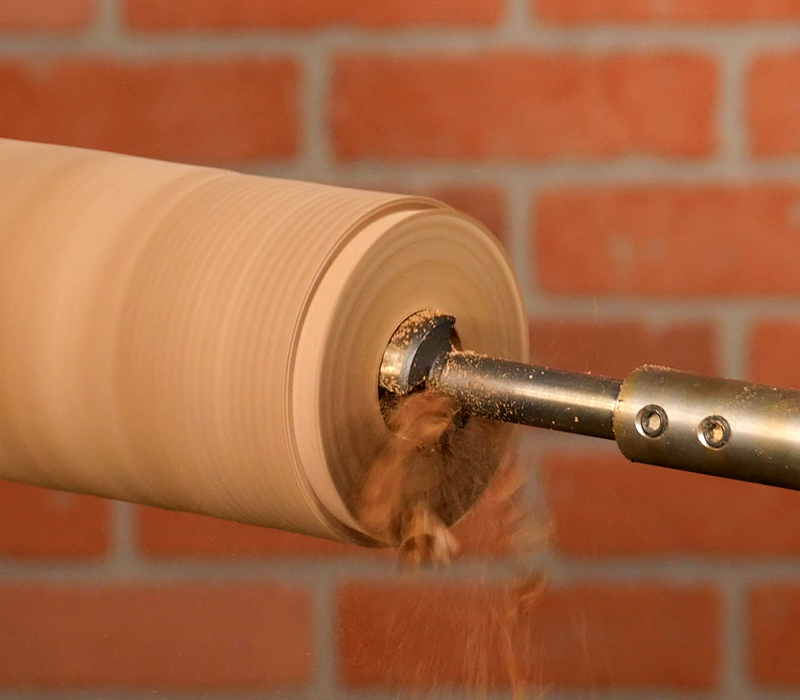

Next we’ll drill the mill body. This part of the process is a little tedious but it’s very important to be precise. I like to drill on the lathe using a drill chuck to hold the bit in the tailstock. Start by mounting the top end of the mill body in a chuck and squaring the bottom of the blank.

Now drill a 1-5/8” diameter hole 1/2” deep.

Next, mount a 1-1/16” forstner in a drill bit extender and a hole half way through the mill body. Don’t worry about drilling exactly half way, just get close. Remove the mill body and turn it around, securing the bottom in the chuck. Finish drilling the 1-1/16” hole from this end until you’ve drilled a hole all the way through. Even on a shorter mill I recommend drilling from both ends and meeting in the middle, this will ensure a straighter hole than drilling all the way from one end.

Remove the mill body and mount the mill head in the chuck. Square the end of the spigot. Now slowly turn the spigot down, testing the fit with the mill body as you go. You want a slip fit that isn’t too tight or too loose.

Once you get the spigot sized, drill a 9/32” hole completely through the mill head.

Now turn a 1/16” deep recess in the end of the spigot to fit the turn plate. This will help center the turn plate during final assembly.

Now that we’re done drilling it’s time to prep for turning. Mount a 2” to 3” waste block on the lathe either in a chuck or on a faceplate. Turn a 1/2” long tenon to fit very snugly into the 1-5/8” diameter hole in the mill body. Make sure to leave a small shoulder around the tenon to give room for your tools when turning later. As you go test-fit the size of the tenon until you have a snug fit.

Mount the bottom of the mill body onto the drive tenon, then mount the mill head into the body and bring in a revolving center into the 9/32” hole of the mill head for support. Now for the fun part – turn the body to shape. Just make sure you don’t turn the walls too thin.

Sand the blank through at least 600 grit.

Pro Tip

After sanding, lightly spritz the blank with water to raise the grain. Then cut it back with steel wool or a fine grit abrasive pad like Mirlon.

Apply a finish to the mill. I’ll use Deft Clear Wood Finish cut 50% with lacquer thinner, it’s a durable finish that is close to the grain and easy to maintain.

Now that your blank has been finished it is time for assembly. Lay the parts out on the bench. Every mill we sell comes with these instructions that you’ll find helpful with this part.

Pepper Mill Instructions

Salt Mill Instructions

Assemble the Mill

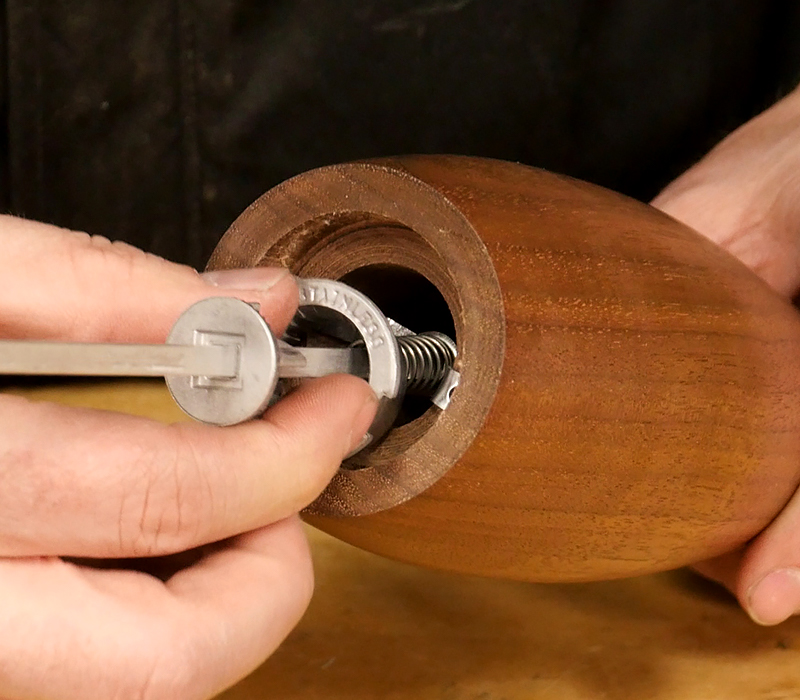

Find the turn plate and the retainer bar, both will be labeled in the instructions, and use them to mark the screw holes in the spigot and mill bottom. Then use a 1/16” drill bit and pre-drill holes about 1/2″ deep. Screw in the turn plate.

Once that is secure, thread the rod through the parts in this order: first the male grinder, then the female, then the spring, and finally the spring bar. Now insert the rod through the mill body and mill head and secure with the adjustment knob.

The last step in assembly is to screw in the retainer bar in the bottom of the mill.

What if My Rod Extends Beyond the Mill Head?

Before we go I’d like to address what to do if you finish this step and find that you may have incorrectly measured drill depths and the threaded rod extends out of the mill head too far.

Luckily this can be fixed with very little work. Pull the mill head until it stops and measure the gap between the head and the body. Disassemble the mill and remove the rod.

Mark the distance measured on the non-threaded end and use a saw to remove the excess.

Then secure the rod in a vice and use a hammer to gently peen the end back into shape. Reassemble the mill. We now have a beautiful pepper mill which goes great by itself or even better next to a turned salt mill.

Supplies Used:

Deluxe Mill

1-1/16″ & 1-5/8″ Forstner Bits

Drill Bit Extender

Spindle Roughing Gouge

Spindle Gouge

Parting Tool

Narrow Parting Tool

Skew

Chucks and Jaws

Sandpaper

1500 Grit Mirlon Scuff Pad

Deft Clear Wood Finish

I am new to turning, I found video helpful.

Hi Mike, Do you have a pepper mill video showing the steps for turning a shaftless grinder pepper mill?

I find that the steps are more complex and the drilling process seems to confuse me. Also Is there any such turning instruction or description to turn a long cylinder into a pepper mill on one end and have a salt grinder on the other end using shaftless mechanism’s? Great Video and thanks for posting it.