Learn how to turn a bottle stopper with square sides using standard bottle stopper kits.

Prepare the blank

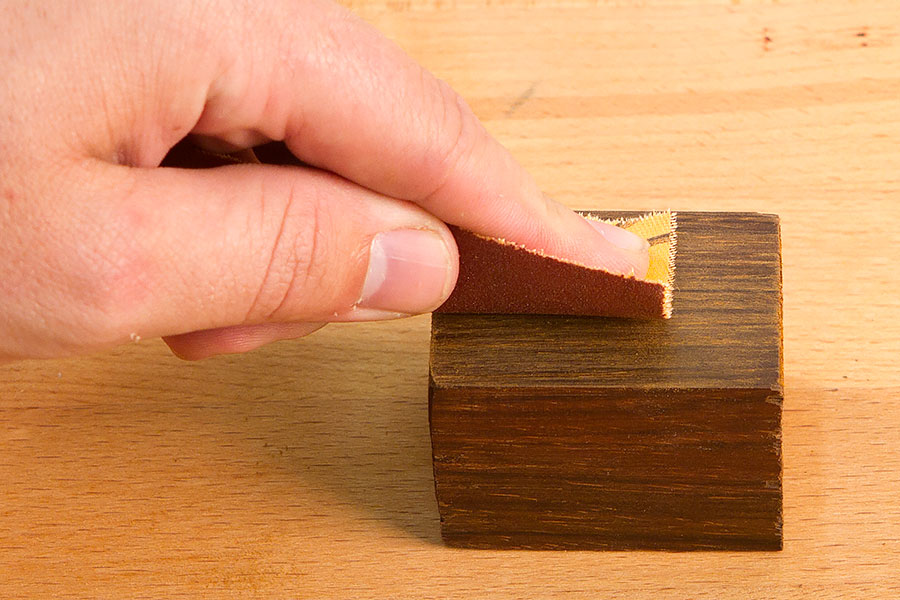

Choose a suitable hardwood blank that is 1-1/2″ x 1-1/2″ x 2″ long. Make sure the blank is square. Cut the ends of the blank square and mark the center of each end. Sand all four sides of the blank to 220 grit.

Mount an 11/32″ drill bit in the drill press. With the drill press stopped, check to make sure the bit is square with the drill press table. Drill a hole 1″ deep in the center of the blank.

Tip: Wrap masking tape around the drill bit to act as a quick depth gauge. Clamp the blank securely in a bench vise. Using a 3/8″-16tpi drill tap in a variable speed drill, tap the hole in the blank. Go slowly.

Turn the Blank

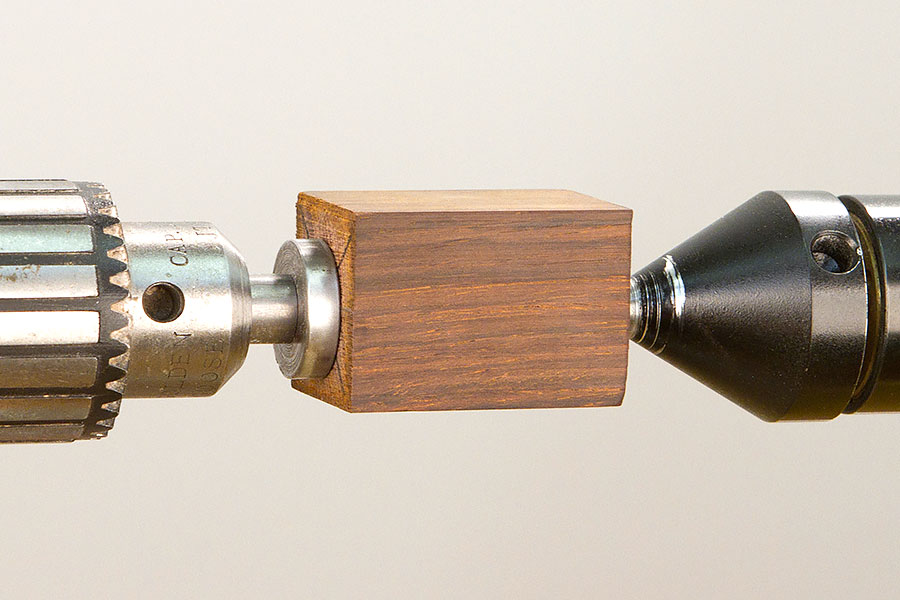

Mount the bottle stopper mandrel and bushing in a Drill Chuck mounted securely in the headstock of the lathe. Screw the threaded blank onto the mandrel until it seats firmly against the mandrel bushing. Slide the tailstock and revolving center into place to support the blank during rough turning. Turn the blank to your desired shape while leaving a part of the blank square using a 3/8″ Spindle Gouge or 1/2″ Skew Chisel.

Sand and Finish the Stopper

Sand with the lathe on while keeping your fingers clear of the square sides. Slide the tailstock out of the way to sand and finish the end of the blank. Remove the finished stopper from the mandrel. on a flat surface sand the square sides of the blank removing any tear-out from turning. Sand and finish the blank.

(Optional Step)

Test fit the blank onto the stopper and check for proper alignment, once satisfied with the fit place a few drops of Five-Minute Epoxy or Thick CA Glue into the threaded hole in the bottle stopper. Screw the bottle stopper onto the threaded stud on top of the bottle stopper. Make sure the wood seats firmly against the stopper for a proper fit.

Interesting. Great use of scraps of exotic woods.